DIY Racks for Your Warehouse

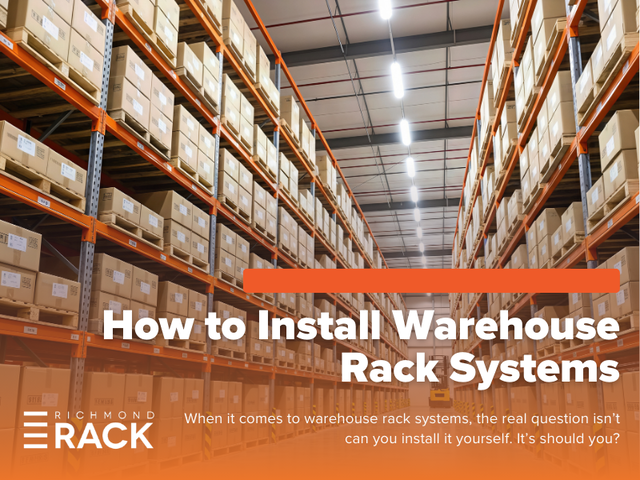

How to Install Warehouse Rack Systems

Need to add a couple of aisles? Reconfigure that strange corner in your warehouse? Maybe you’re converting unused space into active storage and thinking about installing a pallet rack yourself.

If you’ve been in the warehouse business long enough, it can feel doable. You know your boltless rack. You’ve installed wire decking before. You’ve adjusted beams. There’s a slow season coming up, and your maintenance team is sharp. A few handy folks from production are willing to pitch in.

Why not give it a go?

It’s a familiar story. If you’re a homeowner and even remotely handy, you’ve probably looked at a renovation project and thought, “How hard could it be?” And yes—sometimes it works out. Other times… well, that’s the plot of a lot of classic comedies.

When it comes to warehouse rack systems, the real question isn’t can you install it yourself. It’s should you?

The Appeal of DIY Warehouse Racking

On the surface, installing a pallet rack seems straightforward. Uprights, beams, wire deck. Add some guard rails. Maybe some carton flow lanes or gravity conveyors for efficiency.

The components are modular. Manufacturers like Steel King and Richmond Rack design their systems for flexibility and scalability. You can expand rows, adjust beam levels, and reconfigure layouts.

But here’s the key distinction: modular doesn’t mean casual.

Every pallet rack installation is, at its core, an engineered structure. It’s designed to hold thousands—sometimes millions—of pounds of inventory over its lifetime. The difference between “it stands up” and “it performs safely for 20 years” is engineering.

What Looks Simple Is Actually Structural Engineering

Let’s take the pallet rack as an example.

- Upright frames are engineered based on steel thickness, bracing configuration, and height-to-depth ratios.

- Beams are selected according to span and pallet load.

- Wire decking must match beam type and capacity.

- Anchoring requirements vary depending on slab thickness and seismic zone.

Companies like Steel King publish detailed load tables for upright and beam capacities. Richmond Rack carefully designs systems to meet ANSI and RMI (Rack Manufacturers Institute) standards. These aren’t suggestions—they’re structural calculations.

If you miscalculate beam capacity or overload a bay, failure isn’t gradual. It can be catastrophic.

And that’s just a static pallet rack. Add carton flow systems, and now you’re dealing with precise slope calculations, roller spacing, brake configurations, and load sequencing. Install gravity conveyors, and suddenly floor flatness and transition points matter more than you expected.

It’s not just storage. It’s controlled movement of weight.

Codes, Permits, and Compliance

Beyond engineering, there’s compliance.

Warehouse rack systems are regulated. Depending on your location, you may need:

- Building permits

- Engineered stamped drawings

- Seismic calculations

- Fire code compliance (including flue space requirements)

- Sprinkler system adjustments

City codes and ordinances vary. In many municipalities, adding a new pallet rack over a certain height triggers permit requirements. In seismic zones, anchoring and bracing rules are strict.

DIY installations often skip this step—not intentionally, but unknowingly. That can create liability issues, insurance complications, and delays down the road.

The cost of correcting a non-compliant installation often far exceeds the savings of doing it yourself.

The Hidden Variables in Warehouse Rack Installation

Let’s talk about what experienced rack installers know that most DIY teams don’t.

- Slab quality and thickness matter for anchoring.

- Beam connectors must be fully seated and locked.

- Frame plumbness affects long-term stability.

- Shim placement must be precise.

- Guard rails and column protectors must be positioned to prevent forklift impact.

Even wire deck selection isn’t random. Decking style must match beam step depth and load rating. Carton flow beds must align perfectly or they’ll cause product hang-ups and uneven wear.

Professional installers don’t just “put it together.” They install it square, level, anchored, and compliant. The first time.

Why Partnering with Richmond Rack Makes Sense

If you know your warehouse operation well, that’s actually a huge advantage. You understand your SKUs, your throughput, your equipment, your constraints.

When you partner with professionals like Richmond Rack, that operational knowledge becomes part of the design process. Together, you can:

- Optimize aisle layout

- Plan for future expansion

- Account for current lead times and product availability

- Select appropriate pallet rack systems

- Incorporate carton flow or gravity conveyors where needed

- Ensure compliance with current codes and safety standards

Manufacturers like Steel King offer excellent technical resources and high-quality engineered systems. Richmond Rack brings design expertise, permitting knowledge, and professional installation experience to ensure those systems perform exactly as intended.

Instead of guessing at beam capacities or anchoring details, you get engineered drawings. Instead of hoping your layout works, you get a plan optimized for safety and efficiency.

DIY vs. Done Right

There’s nothing wrong with being hands-on. In fact, the best warehouse managers are deeply involved in their facilities.

But warehouse rack installation isn’t hanging shelving in your garage. It’s installing a structural storage system that supports heavy inventory, protects your team, and impacts your productivity for years to come.

Sure, you and your maintenance crew might be able to assemble a few bays. But if something shifts, fails inspection, or doesn’t perform as expected, the risk isn’t funny.

Let the professionals design it.

Let them engineer it.

Let them install it safely, the right way, the first time.

Then, once the new aisles are up, the guard rails are set, the pallet rack is fully loaded, and your operation is humming—

You can all share a laugh about how close you came to turning it into a comedy show.

Ready to Get It Done Right?

If you’re planning to install a pallet rack, add carton flow, reconfigure aisles, or expand your warehouse storage system, now is the time to talk to the pros.

Connect with the experts at Richmond Rack to review your layout, confirm load capacities, navigate permits, and ensure your warehouse rack installation is engineered for safety and long-term performance. Whether you’re adding a few bays or redesigning your entire facility, their team can help you plan it correctly—from concept to final anchor bolt.Don’t gamble with your warehouse infrastructure. Reach out to Richmond Rack today and make sure your next rack project is done safely, efficiently, and built to last.