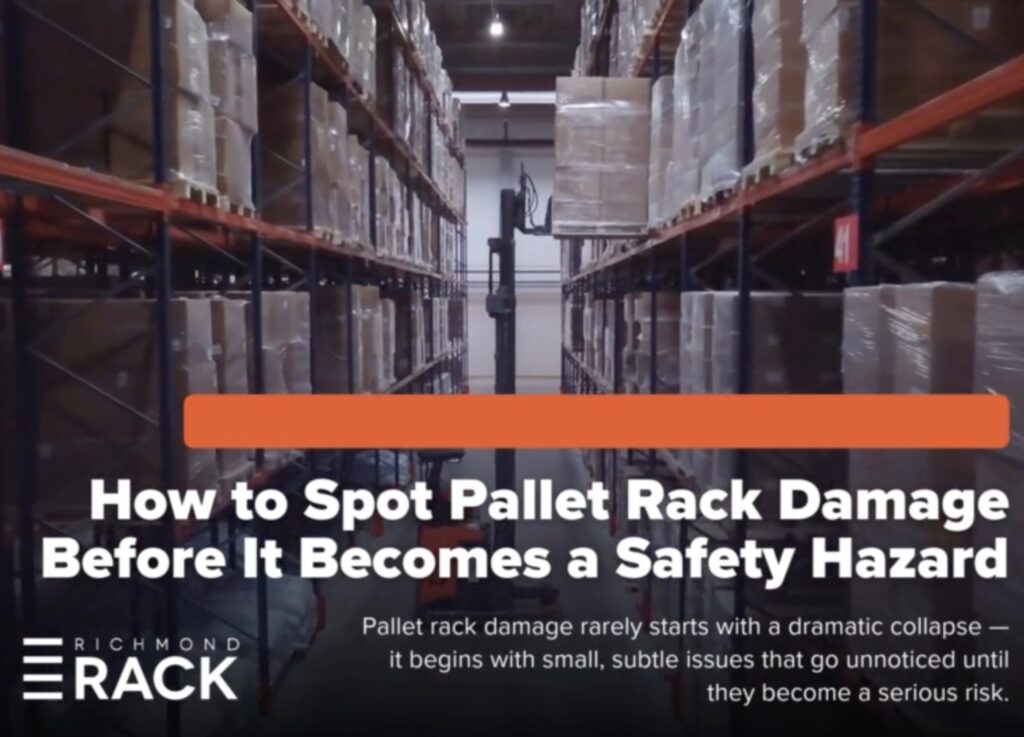

How to Spot Pallet Rack Damage Before It Becomes a Safety Hazard

Pallet rack damage rarely starts with a dramatic collapse — it begins with small, subtle issues that go unnoticed until they become a serious risk. In a busy warehouse, where forklifts are moving constantly and loads vary by weight and size, even minor rack damage can compromise the structural integrity of your system.

The good news: most racking failures are preventable. By learning what early warning signs look like and inspecting your system regularly, you can protect your team, your inventory, and your operation from unnecessary disruptions.

At Richmond Rack, we help facilities identify and correct racking damage every day. Here’s what we recommend watching for during your own inspections.

1. Leaning or Uneven Uprights

If an upright isn’t perfectly vertical, something is wrong.

Leaning uprights are often caused by:

- Forklift impacts

- Overloading

- Poor anchoring

- Compromised footplates or base plates

Even a slight lean puts unbalanced pressure on beams and connectors, increasing the chance of a failure. Uprights should always stand plumb — anything noticeably off-center is a red flag that needs immediate evaluation.

2. Beam Deflection Beyond Safe Limits

Some beam deflection is normal under load. Excessive deflection is not.

A safe guideline: If the beam bows more than 1/180th of its length, it’s considered unsafe.

For example, a 96-inch beam should not deflect more than half an inch.

Common causes include:

- Overloaded pallets

- Incorrect beam type for the application

- Uneven load distribution

- Previous damage that weakened the beam

If a beam stays bent even after the load is removed, it should be replaced — not repaired.

3. Damaged or Missing Safety Clips and Beam Connectors

Clips and connectors are small, but they play an essential role: they keep beams locked securely into place.

Look for:

- Broken or missing safety clips

- Bent or cracked connectors

- Beams that lift or shift when you push up on them

Loose beams are one of the most common causes of racking collapse. If a beam can be moved by hand, it’s unsafe.

4. Bent, Torn, or Punctured Upright Columns

Uprights take the brunt of forklift traffic, especially in high-volume or narrow-aisle operations. Damage often occurs at the lowest 24 inches of the upright.

Key warning signs:

- Kinks or bends in the upright column

- Tears in the steel

- Punctures from forklift forks

- Buckling at the bracing connections

Even a small bend can reduce load capacity dramatically — sometimes by 30% or more.

Installing column protectors or end-of-aisle guards can prevent recurring damage, especially in high-traffic zones.

5. Missing or Damaged Bracing

Bracing gives your rack its strength and rigidity. When bracing is missing, bent, or detached, the entire system becomes unstable.

During inspections, check for:

- Horizontal or diagonal braces that are bent

- Welds that have cracked

- Braces missing completely across an upright frame

Bracing issues often signal forklift impact and should be addressed immediately to prevent structural failure.

6. Loose or Improper Anchoring

Anchors secure uprights to the concrete floor. If anchors are loose, missing, or improperly installed, the rack can shift under load.

Look for:

- Uprights that rock when pushed

- Missing anchor bolts

- Anchors pulled out of the concrete

- Visible cracking around anchor points

Any movement at the base is a serious hazard — especially in seismic regions.

When to Call a Professional Rack Inspector

Internal inspections are important, but a trained rack inspector can identify deeper structural issues that aren’t visible at a glance. Richmond Rack recommends a professional inspection:

- Annually for most facilities

- Semi-annually for high-traffic or high-volume operations

- Immediately after a forklift impact

- When reconfiguring or adding rack capacity

- When changing load types or weights

An expert inspection helps ensure your system meets both OSHA and RMI (Rack Manufacturers Institute) guidelines — and gives you a clear plan for repairs, replacements, or reconfiguration.

Don’t Wait for Damage to Turn Into Downtime

Rack failures are expensive. They damage inventory, cause operational delays, and — most importantly — put people at risk. By learning the early signs of pallet rack damage and addressing issues quickly, you can maintain a safer and more productive warehouse environment.

If you’re unsure about the condition of your racking system, Richmond Rack can help. Our team provides full rack inspections, damage assessments, and professional recommendations to keep your warehouse compliant, efficient, and safe.